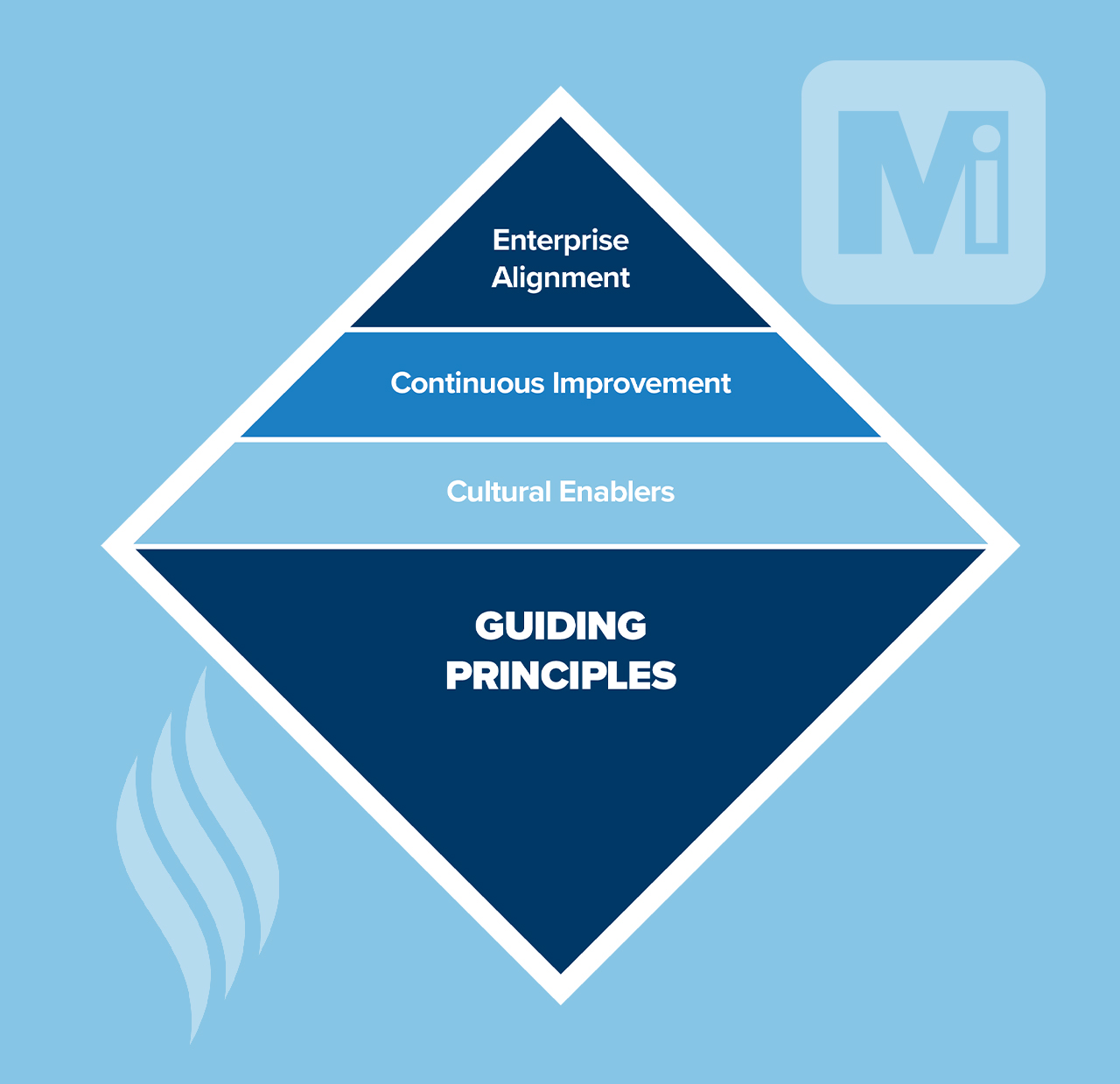

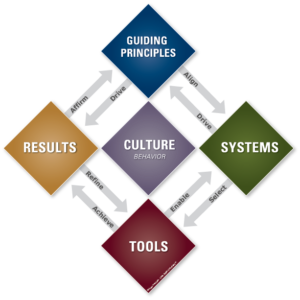

The Shingo Model™

The Shingo Model captures the important relationship between principles, systems, tools and results, and need to be embedded in the culture.

Guiding Principles

Divided into three dimensions, Cultural Enablers, Continuous Improvement and Enterprise Alignment.

The Shingo guiding principles are the bedrock for building a sustainable culture of organisational excellence.

Tools

Tools do not answer the question why they only focus on how, this problem often leaves team members waiting for instructions or powerless to act on their own.

Systems

All work in an organisation is the outcome of a system.

Organisational excellence requires well-designed systems to drive the ideal behaviours that are required to produce sustainable results.

Results

The term KPI is extensively used in many businesses to measure success.

Lagging KPI’s (not KBI’s) are often used to measure behaviour, which reflects culture. KPI and KBI’s are different but inextricably linked to results.

Culture (Behaviour)

Cultural transformation requires a shift in behaviours and systems drive behaviour.

Shingo helps you adjust the old, create new and eliminate the misaligned systems that no longer drive desired behaviours or support outcomes.

Discover Excellence

Discover Excellence

Discover Excellence is the gateway to the other five workshops in the series. This foundational, two-day workshop introduces the Shingo Model™, the Shingo Guiding Principles, and the Three Insights to Organizational Excellence™. With active discussions and on-site learning at a host organization, this program is a highly interactive experience. It is designed to make your learning meaningful and immediately applicable as you discover how to release the latent potential in an organization to achieve organizational excellence. It provides the basic understanding needed in all Shingo workshops; therefore, it is a prerequisite to all the other Shingo workshops.

As a participant, you will:

• Learn and understand the Shingo Model™

• Discover the Three Insights to Organizational Excellence™

• Explore how the Shingo Guiding Principles inform ideal behaviors that ultimately lead to sustainable results

• Understand the behavioral assessment process through an interactive case study and on-site learning

Systems Design

Systems Design

This two-day workshop integrates classroom and on-site experiences at a host facility to build upon the knowledge and experience gained in the DISCOVER EXCELLENCE workshop, and focuses on the Systems and Tools diamonds in the Shingo Model™. It begins by explaining that all work in an organization is the outcome of a system. Systems must be designed to create a specific end objective; otherwise, they evolve on their own. Systems drive the behavior of people, and variation in behavior leads to variation in results. Organizational excellence requires well designed systems to drive ideal behaviors that are required to produce sustainable results.

In this workshop, you will:

• Discover three types of essential systems

• Explore five required communication tools for each system

• Learn how to create and use system maps. Understand system standard work and how it drives improvement

Cultural Enablers

Cultural Enablers

This two-day workshop integrates classroom and on-site experiences at a host facility to build upon the knowledge and experience gained in the Discover Excellence workshop. It takes you deeper into the Shingo Model™by focusing on the principles identified in the Cultural Enablers dimension:

• Respect Every Individual

• Lead with Humility

Cultural Enablers principles make it possible for people in an organization to engage in the transformation journey, progress in their understanding, and build a culture of organizational excellence. Organizational excellence cannot be achieved through top-down directives or piecemeal implementation of tools. It requires a widespread organizational commitment. The Cultural Enablers workshop will help you define ideal behaviors and the systems that drive those behaviors using behavioral benchmarks.

Continuous Improvement

Continuous Improvement

This two-or three-day workshop integrates classroom and on-site experiences at a host facility to build upon the knowledge and experience gained in the Discover Excellence workshop. It begins by teaching you how to clearly define value through the eyes of your customers. It continues the discussion about ideal behaviors, fundamental purpose, and behavioral benchmarks and takes you deeper into the Shingo Model™ by focusing on the principles identified in the Continuous Improvement dimension:

• Seek Perfection

• Embrace Scientific Thinking

• Focus on Process

• Assure Quality at the Source

• Improve Flow & Pull

The Continuous Improvement workshop will deepen your understanding of the relationship between behaviors, systems, and principles, and how they drive results.

Enterprise Alignment

Enterprise Alignment

This two-day workshop integrates classroom and on-site experiences at a host facility to build upon the knowledge and experience gained in the Discover Excellence workshop. It takes you deeper into the Shingo Model™ by focusing on the principles identified in the Enterprise Alignment dimension:

• Think Systemically

• Create Constancy of Purpose

• Create Value for the Customer

To succeed, organizations must develop management systems that align work and behaviors with principles and direction in ways that are simple, comprehensive, actionable, and standardized. Organizations must get results, and creating value for customers is ultimately accomplished through the effective alignment of every value stream in an organization. The Enterprise Alignment workshop continues the discussion around defining ideal behaviors and the systems that drive them.

Build Excellence

Build Excellence

This two-day capstone workshop integrates classroom and on-site experiences at a host facility to solidify the knowledge and experience gained from the previous five Shingo workshops. The Build Excellence workshop demonstrates the integrated relationships and execution of principles, systems, and tools that drive behavior in a culture toward the ideal while achieving desired results. The workshop addresses the Shingo Model in its entirety by developing a structured approach that will accelerate a cultural transformation.

In this final Shingo workshop, you will:

• Discover how the Shingo Model strengthens the execution of your strategy

• Learn how to shift your culture, guided by organizational purpose, to the next level

• Use Go & Observe to understand the practical application of the Shingo Model

• Accelerate your cultural transformation by applying the learnings gained from the Shingo Model into a PDCA cycle

Achieve Excellence with Shingo

The Manufacturing Institute became Europe's first Shingo™ Affiliate in 2008

-

Shingo: Overview of Organisational Excellence

For a business to be successful, it must never stop improving. Yet such continuous improvement is far from easy – in fact,

-

Throwing The Spotlight On The Shingo Prize

Throwing The Spotlight On The Shingo Prize: How To Achieve It In Your Manufacturing Business Education through the Shingo Model is incredibly popular

-

TMI Helps Jabil Healthcare Bray Win The Shingo Prize

The Manufacturing Institute helps Jabil Healthcare Bray to receive the world’s highest standard for organizational and operational excellence – the Shingo Prize.

-

34th Annual Shingo Conference

Our resident Shingo experts Adrian Healey and Steve Nicoll attended the conference in Orlando on the 19th and 20th May to celebrate